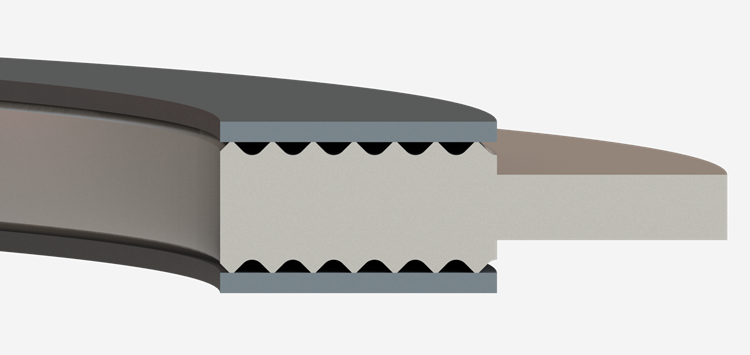

A cross section iillustration of a Kammprofile gasket, with a serrated metal core and outer ring, plus a soft sealing material as a facing (Bild: Flexitallic Group)

31.10.2025 Static Seals for Sealing Hydrogen

A Review of recent public domain papers on sealing tests using hydrogen

Hydrogen has a potentially large role in the future of energy, either as a fuel, as an energy storage vehicle, or both. Due to its inherent properties, there has been some concern about the potential for leakage of hydrogen in this new process industry. This, of course, brings into focus the sealing of static bolted

connections, i.e., bolted flange joints. The most common leakage tests for bolted flange connections use either helium (EN13555), methane (ASME B16.20) or nitrogen (DIN 3535), but not hydrogen. There are good reasons for choosing these gasses, particularly helium, which is safe and a small molecule which can be detected and measured by standard equipment such as a mass spectrometer. Other literature has shown that leak rate of different gases cannot be judged and predicted by molecule size alone, therefore the conversion of leak rate using a standard test and test gas cannot be easily converted to a leak rate of hydrogen. Therefore, testing of gaskets with hydrogen has been required to make engineering decisions.

Hydrogen is well placed to be a key part of any transition towards a cleaner and more sustainable energy economy. Decarbonization of processes such as electricity generation, steel making, and other industrial processes will likely utilize hydrogen as a key part of the process.

It would not be a valuable use of time to spend a large part of this paper discussing the place of hydrogen in upcoming energy transition when there are multiple conferences and publications in this field which cover this subject in more detail. Examples would be publications and events organized by the Fuel Cell and Hydrogen Energy Association [1] and Hydrogen Europe [2].