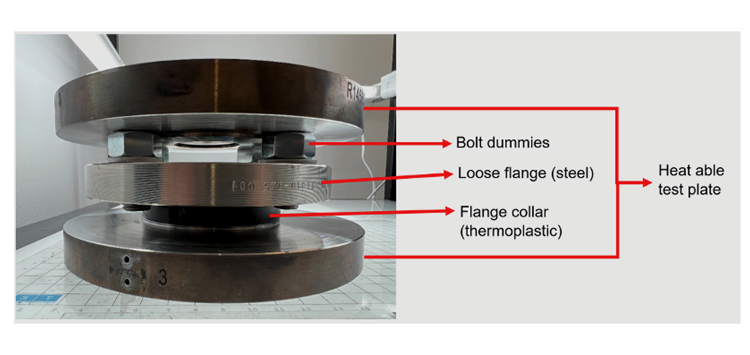

Sandwich structure of the test specimens, in accordance to [11] (right) (Bild: AMTEC)

31.10.2025 Optimizing the design of thermoplastic flange systems

Development of an analytical calculation method

In the course of environmental protection and the amendment of TA Luft, emissions from flange connections must be reduced (to L0.01). The design and calculation of steel flanges is easy to handle with the help of EN 1591-1 [1] and EN 13555 [2]. However, the standards mentioned are not suitable in their current form for thermoplastic sealing joints, such as those used in natural gas supply. For this reason, lengthy and cost-intensive tests must currently be carried out to verify tightness and strength.

The aim is therefore to develop a time-efficient and cost-effective analytical calculation method based on the existing standards. For this purpose, the energy-elastic material parameters of the steel must be replaced by viscoelastic material parameters of the thermoplastics and the calculation algorithm adapted accordingly. The problem is to be investigated with the aid of numerical structural simulations (FEM) and experimental investigations. This is an innovative contribution presenting a research project with high practical relevance for industry.