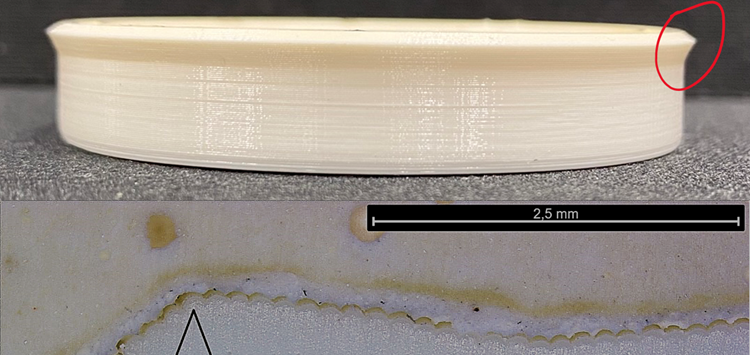

Surface structure and crossection of one dynamic rod seal manufactured by FFF. The arrow marks the seal lip (Bild: University of Applied Sciences Hochschule Emden/Leer)

31.10.2025 Simulation of Leakage Flow in dynamic seals from 3D-printing

A comparison between traditional seals and those produced via FFF manufacturing

Additive Manufacturing (AM) technologies are advancing rapidly, even within the realm of seal production. However, the surface quality of AM seals typically falls short when compared to seals manufactured conventionally. For instance, Fused Filament Fabrication (FFF) yields components with a characteristic string-like surface texture. The dimensions of this texture align with the fluid film thickness of a dynamic rod seal. Through a fluid-structure interaction (FSI) simulation employing coupled Navier-Stokes equations, the fluid flow between the seal and rod can be analyzed. This simulation demonstrates that periodically fragmented contact has a significant impact on the sealing properties of the dynamic seal. A comparison between traditional seals and those produced via FFF manufacturing reveals notable implications, such as alterations in the reverse feed rate through the seal gap.

Additive Manufacturing has made significant strides in recent years and presents itself as a viable alternative for seal production. Seals, being components subjected to wear due to tribological factors, require periodic replacement. The availability of spare parts can be improved through fast and on-demand additive manufacturing. Fused Filament Fabrication (FFF) emerges as a promising production method, particularly for TPU-based dynamic rod seals [1]. Experimental studies have indicated that careful selection of printing parameters and materials results in seals boasting impressive sealing properties [2]. Although the lifespan of FFF seals may be shorter compared to their conventionally manufactured counterparts, they serve as a quick and interim solution to prevent costly machine downtime.